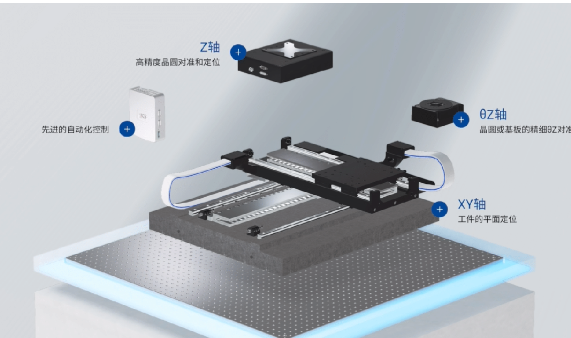

High-precision motion platform for semiconductor wafer inspection

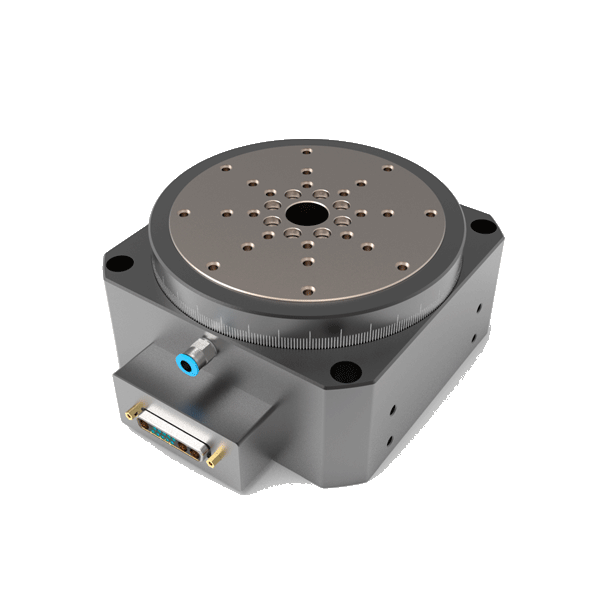

1 Fine rotational indexing and alignment of wafers or substrates

Highly accurate and repeatable 360-degree rotation with no backlash

Magnetic direct drives enable high speed and acceleration

Direct drive provides very low cogging torque and enables smooth speed and low error motion

Ultra-precision air bearings developed and manufactured in-house

Further performance improvements to optimize performance specifications for asynchronous operations

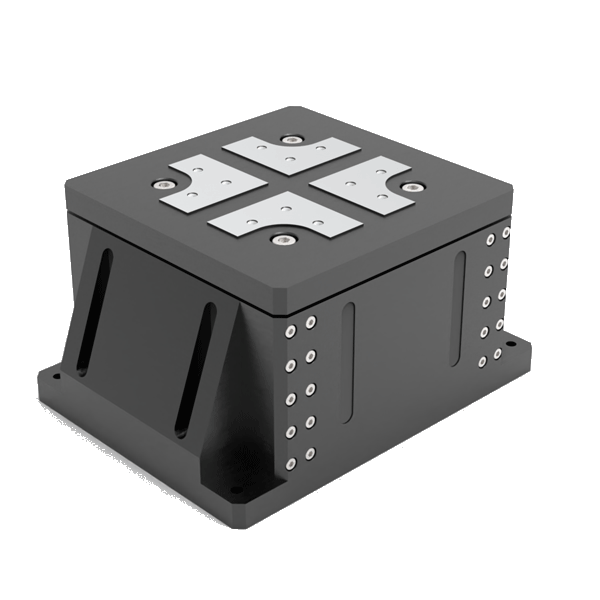

2 Z-axis – precision wafer alignment

Excellent design with low profile height, high load and compact structure

Direct-drive enables zero cogging, smooth motion in nanoscale steps, and fast response

High-resolution encoder enables nanoscale positioning of motion platforms

Pneumatic balancing system prevents motor overheating and avoids collisions

Affordable and fast delivery

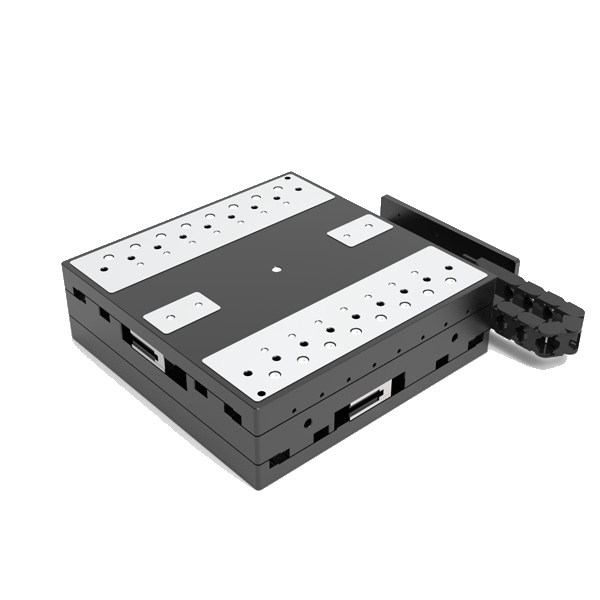

3 XY axis – precision stepping and stable motion

Highly dynamically coupled ironless linear motors mounted on the base shaft for powerful, fast precision movements

Dual encoder system ensures motor alignment with deflection angle while achieving high resolution and accuracy

Low profile multi-bearing rigid platform reduces Abbe deflection and enables greater flatness and straightness

Designed for high flexibility and customization

Optimized integrated cable management reduces movement resistance and extends service life

Granite base ensures high performance of the motion system

Optional active vibration isolation system

Film Thickness Measurement Applications

During the semiconductor manufacturing process, multiple dielectric layers are deposited on the silicon wafer

Film thickness measurement for measuring the correct thickness of each layer

Usually the optical technique "ellipsometry" is used

Ellipsometry measures the degree of polarization of light after reflection on the surface of a film, allowing the thickness of this layer to be determined down to the angstrom level